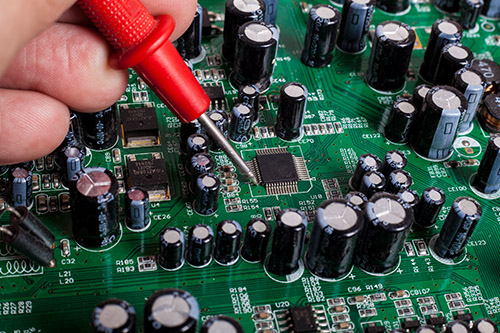

Used to inspect features of prototypes and mass production products such as soldered parts on mounting boards, through holes, and wafer pattern circuits. With the Hirox original rotary-head adapter, easy inspections of cracks and flux are possible and simple to carry out

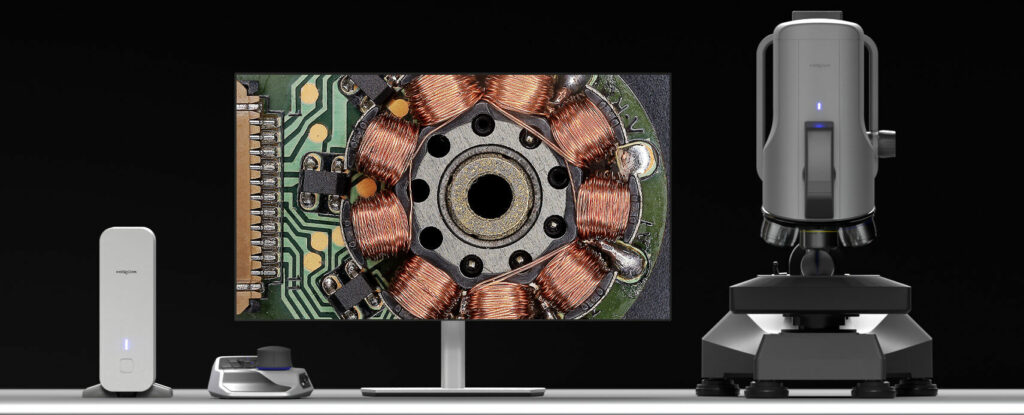

3D DIGITAL MICROSCOPE

40 years ago, Hirox invented the first video microscope.

Today, strong with our tradition of high quality optical manufacturing, we are reinventing 3D Digital Microscopy to offer you an instrument easier, faster and stronger than ever.

What’s a Digital Microscope?

A digital microscope (DM), is a microscope that has a camera (CMOS) attached instead of an eyepiece and displays the digitally acquired image on a large monitor. In addition to observation, it can also have various extended functions such as dimension measurement, recording of still images and moving images. It is used in a wide range of scenes such as research and development, production technology and quality assurance of various private enterprises and government agencies with stress-free observation environment and ease of handling.

Digital Microscope Technology

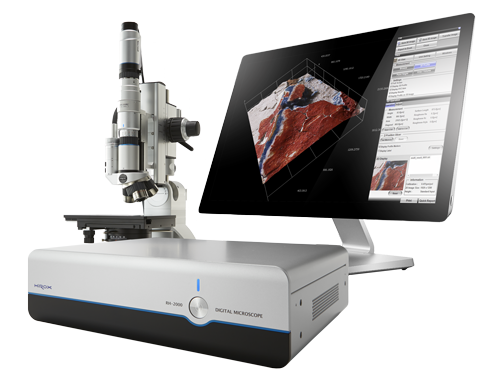

The Hirox digital microscope is a system with a main unit, lenses attached to a camera that maximizes lens performance, optimal lighting for objects, precisely controllable stands, usability-rich applications, and comfortable observation. Furthermore, ACS communications makes it possible to control speed based on lens information, instant measurement on the monitor, automatic judgment of shooting conditions according to the operation of an operator, and to observe, capture, and measure by intuitive operations of the user. Hirox Makes it possible to observe, capture and measure with smooth, intuitive operation.

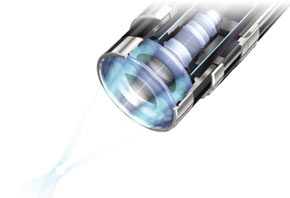

Lens Made by Lens Manufacturer

In the 1920s, Hirox began making lenses. Since then Hirox has produced various lenses for reflex cameras, TV cameras, and 8mm film cameras. With the lens know-how cultivated through lens development and production, Hirox has created a number of proprietary lenses and optical adapters. Providing clear and easy observation with a lenses that have both a large depth of field and high resolution.

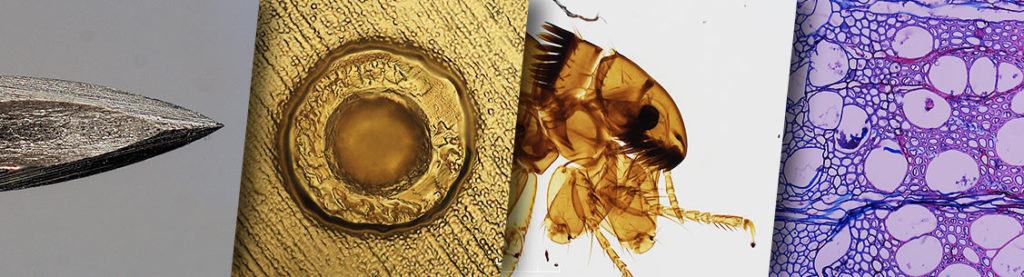

Exceptional flexibility for a wide range of applications

Our special stands for inspection and 3D measurement of printing cylinders and plates, as well as special software and lenses to measure depth and length of printing patterns make Hirox the number one partner for your measurement needs in the printing industry, coin manufacturers and more.

Whether there is a request for inspection of paint, wood, textile, metal, resin, rubber, biological, or other objects, it is possible to cover with the versatility of the digital microscope. With a zoom range from 0x up to 10000x, it shows the detailed condition of the object, supports cultural heritage analysis and conservation.

Applications such as turbine inspection of jet engines, development of space rockets, new material research and more. Select the lenses according to the application, from macro lenses or handheld observation up to ultrahigh magnification for grain structure analysis, defects, quality assurance…

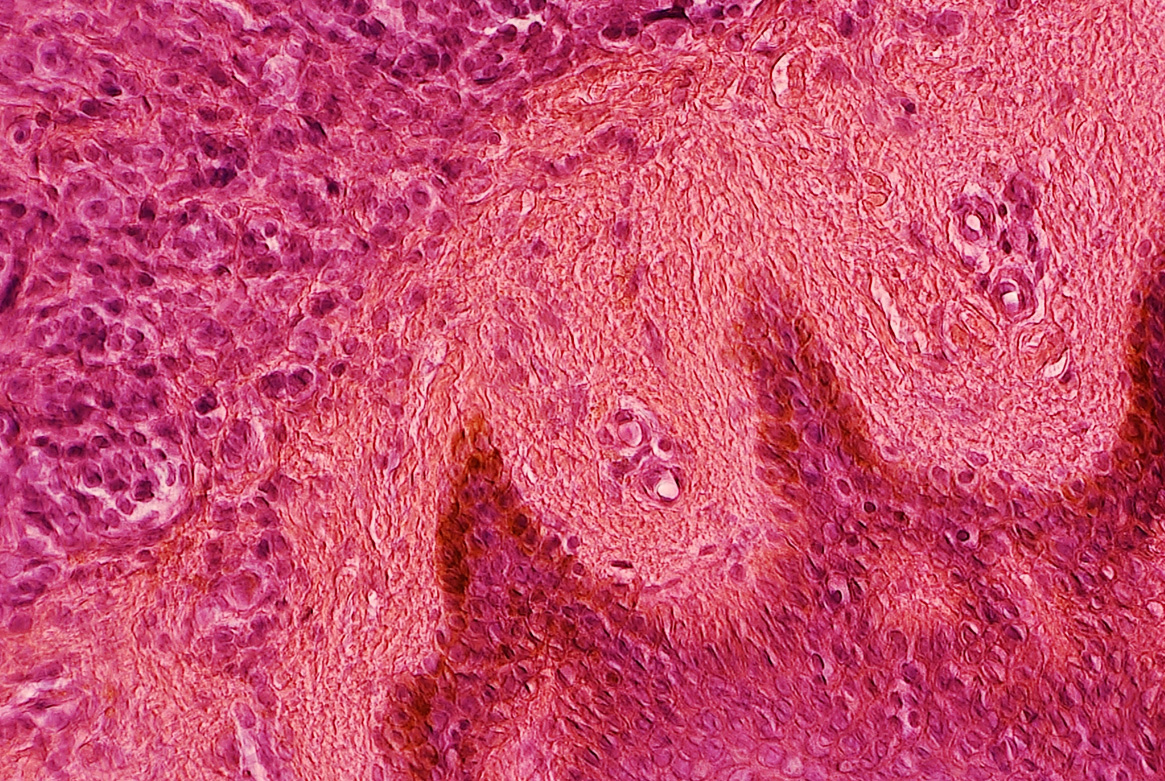

Whether it’s for plant cell observation, entomology or contamination analysis, Hirox is highly flexible. Using LED lighting, organic samples can be observed thoroughly without the influence of heat on the sample and transmission or polarisation will give excellent results!

Inspection of powder, crystals, emulsion, medical instruments such as injection needles and stents can be operated with high versatility and precision. Additionally, the timer recording and particle counting functions that can be used for follow-up observation are included. Ideal for R&D, analysis and high-quality imaging.

The DM is used for research and development, production, and quality assurance, in applications such as checking the finished dimensions of molds, mass-produced products, and failure analysis. It can also measure surface irregularities as well as surface condition.

Hirox unique flexibility is ideal for a wide range of applications in the fields of Forensics: whether it’s for questioned documents, counterfeit, ballistics, tool marks, legal medicine, drugs or electronics, our system can be stationary or portable and is ready to go where you need it!

HIROX Designed Original

”Rotary-Head” Adapter

The patented Hirox motorised rotary head adapter creates a unique 360° “helicopter view” observation over an object: discover inaccessible details without any manipulation of the sample. Depending on the adapter, the high precision mirror sets allow inspection from 25 degree up to 55 degree, and thanks to video recording, you will be able to capture stunning & informative videos.

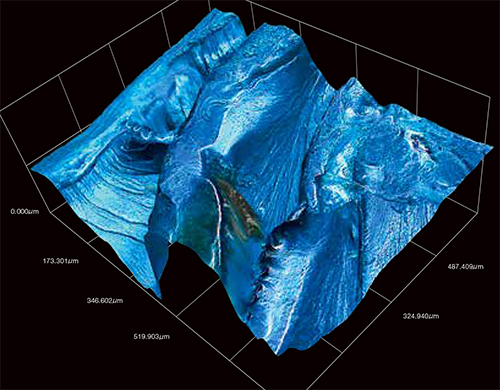

Super Fast 3D Multi Focus

& Accurate Measurements

Fast and accurate Z axis scanning with an integrated stepping motor creates high precision 3D Modeling data. 3D model information can be displayed as original color, pseudo color, or as a wireframe, maximizing the amount of information that can be taken from a 3D model. Multiple measurement features are available including height, profile, volume, roughness and much more!

Lighting Technology

In magnification observation, lighting technology is regarded as important as lens performance. Hirox lighting technology suppresses the reflection of glass and metal, like the lamp in the picture below. It enables real observation. With a 30,000 hour lifetime and 5700K light guide for more flexibility and power.

Best Imaging technology

State-of-the-art CMOS sensor with improved light sensitivity and very low image noise. The resolution is higher than Full HD, at a very fast 50 FPS. You can display on 4K, create high quality images, wide panorama stitching & high-resolution videos.